2005 Ford Mustang

2005 Ford Mustang Overview

The 2005 Mustang was a completely redesigned model from the ground up including new suspension, body panels and motors for the V6 and GT model. The look for the new 2005 Mustang was designed to incorporate some of the defining styling cues from the popular, 1965 to early 1970’s cars. It was clear that Ford had really stepped up their game with the S197 and they now had a car that was clearly ready to take on the 21st century.

| Model: | 2005 Ford Mustang |

| Generation: | 5th Generation Mustang |

| Type: | 2 Door |

| Body Styles: | Coupe, Convertible |

| Engines: | 4.0L SOHC EFI V6, 4.6L 3V EFI V8 |

| Original Price: | $19,410 (Base Coupe), $25,320 (Basic Convertible) |

| Units Produced: | 160,412 |

Additional 2005 Mustang Research: 2005 Research Center / Colors Details / Production Numbers / Prices & Options / Sales Brochures / Owner Manuals / Maintenance / Pictures / Videos / VIN Decoder / Special Editions

Background & Details

The 2005 Mustang got an all new chassis, design and a host of upgrades under the skin that made this one of the most meaningful updates in Mustang history.

If the all-new 2005 Mustang reminds you of the 1967/8 Mustang, then Ford achieved its goal. Ford wanted to use the new generation Mustang launch as a chance to bring things back to the glory days. The lines are smooth and the triangular rear window brings back that twinge of nostalgia.

Visually the Mustang has the gas cap on the drivers side behind the rear wheel. The side scoop is not a full indent, but rather an indent at the bottom and an upsweep just ahead of the rear wheels. The GT grille has two round fog lamps set in a few inches from the outside of the grille and has a Running horse in the grille’s center. On the front fender there is the highly recognizable GT badge that lets the casual observer know this is one hot machine. Ford designed a good looking interior for the 2005 Mustang with nice rounded gauges and a console to house the shifter were added, along with supportive seats and lots of leg room too.

Engine & Powertrain

There were two engine options for the 2005 Mustang range. The base model came with a SOHC V6 while the GT got a 4.6 liter 3 valve V8. Power ratings on the V6 were 210 hp and 240 lb/ft torque. The V8 was rated at 300 hp and 320 lb/ft torque. Behind these engines is a standard 5 speed transmission, and optional 5 speed automatic is available. The GT gets a Traction Loc control rear axle. The V6 has a 3.31:1 open rear axle and the V8 gets a 3.55:1 limited slip axle.

The standard engine was a 60-degree 4.0-liter SOHC V6 known as the Cologne V6. It was all new and replaced the 3.8 liter 90-degree pushrod engine in the 2004 model. The 210 horsepower was 23 horsepower more powerful and the 240 pound-feet of torque was 15 pound-feet over 2004, both big improvements. The new V6 was a smoother and more compact engine with great power and torque relative to the competition. The 4.0-litre six felt strong enough to be entertaining and while it wasn’t the smoothest or sweetest sounding V6 ever produced it was a vast improvement over the lumpy old 3.8 that was used in the previous car.

The 4.6-liter all-aluminum V8 found in the 2005 GT had three-valve heads and was good for 300 horsepower. It had an aluminum block so weight was down 75 pounds versus the prior years cast-iron design. 40 more horsepower than the 2004 engine and less weight to boot, thats a big win for Ford engineers. Overall performance improved with 0 to 60 mph for the 2005 GT taking only 5.1 seconds and the quarter mile only 13.7 seconds.

The dual exhaust system on the Mustang sounds great. It is a 2.5″ mandrel bent setup with a crossover pipe and stainless steel tips. The dual mufflers are located just behind the rear axle.

Both engines were mounted to the vehicle with new hydraulic engine mounts that prevent any unwanted vibrations from entering the cabin. Transferring power back to the rear wheels was handled by a pair of five speed manual transmissions as standard equipment on both the base V-6 and GT V-8. The V-6 received a Tremec T-5 while the Tremec 3650 gearbox was used once again in the GT. Both transmissions had revised gearshift linkages to improve shift response and feel.

Also new was a hydraulic actuated clutch that greatly reduced the pedal pressure required to engage and disengage. This also reduced maintenance as the new system was self adjusting and eliminated the possibility of being stranded on the side of the road with a broken clutch cable. While they were at it engineers also specified new clutch disc materials in the V-6 cars for better durability and the V-8’s got a larger clutch assembly in order to handle the increase in power.

For those who weren’t thrilled with the prospect of three pedal driving an all new automatic transmission was optional in both the V-6 and V-8. Lifted from the Ford Thunderbird and Lincoln LS the Ford-built 5R55S transmission was a smooth shifting 5-speed unit that brought new levels of civility and performance never before seen in a self shifting Mustang. This sophisticated transmission featured a direct-drive fourth gear and overdrive fifth allowing engineers to use closer spaced gear ratios for better acceleration while still being able to attain decent fuel mileage on the highway.

A power-train computer controlled shift timing and duration with the capability of communicating with transmission 10 times faster than before. This allowed power-train engineers to better match the transmission shift characteristics with the new electronic throttle controls and the VCT on the V-8 engine. The result was Mustang that could accelerate aggressively when the driver desired or could cruise around offering buttery smooth, seamless shifts that are barely perceptible to the driver. Traction control was available once again however now the system was more sophisticated. The system was standard on the GT and was available as a package that included anti-lock brakes on V6 models. An optional four-channel anti-lock braking system was available for a greater degree of brake control. It used electronic sensors to constantly monitor road conditions and feed the information to a dedicated control computer capable of determining, within milliseconds, whether the vehicle is on dry pavement or negotiating a slippery surface. When traction control isn’t desired drivers can deactivate the system with a simple button on the instrument panel.

Another area of much needed improvement was the brakes. The standard four-wheel disc brakes had the biggest rotors and stiffest calipers ever fitted to a mainstream Mustang (about time). Twin-piston aluminum calipers clamp down on 12.4-inch ventilated front brake discs on GT models while the V-6 Mustangs get 11.4-inch ventilated rotors that also are 30 mm thick. In the rear, the brake rotors are 11.8 inches in diameter. Rear rotors were vented on the GT and solid on the V6.

Chassis & Suspension

The 2005 Mustang chassis was new from the ground up.

Hiding beneath the S197’s new architecture was an all new suspension system that would finally rid engineers of the compromises that had to be made with the old Fox/Fox-4 platform and suspension used in the past. Up front chassis engineers took inspiration from BMW and its fabulous M3. Lighter springs were mounted around the MacPherson struts allowing engineers more precision when tuning the shock valving. The lower suspension was located via unique L-shaped control arms. What made these control arms so unique was how they were made. Engineers managed to come up with a ground breaking new technology to manufacture these control arms out of less expensive steel yet were super strong and weighed less than comparable cast-aluminum designs.

Bushing selection was a key element to how the new L-shaped control arm performed. Firm bushings were used to locate the forward leg of the L-arm to the body structure. This quickened steering response and helped control the side to side motions of the arm under loads. A softer bushing was installed on the rear leg of the arm and this helped quell the transmission of unwanted road shocks to the body. An anti-roll bar was installed to limit body roll. A 34mm bar was used on the GT while the Base V-6 had a smaller 28.6mm bar. The system was simple yet it went a long way to improving the Mustang’s ride quality and handling response all at the same time.

At the rear a solid rear axle was once again chosen much to the surprise of many enthusiasts. Rumors had persisted that the S197 would have an independent rear suspension similar to that used on the Lincoln LS and Thunderbird. After much debate and input from hardcore Mustang enthusiasts engineers choose to go with the solid axle as it was deemed to better suit the Mustang’s character. It was also the preferred choice of the amateur drag racing crowd and was cheaper to build. For those Mustang enthusiasts (such as myself) who longed for an independent set-up and were disappointed, Ford promised an upper level Mustang equipped with IRS for the future.

While a solid rear axle suspension may seem like a step back the design that engineers came up with was quite well designed and worked very well. The four link, Quadra-shock rear suspension from the SN95/Fox-4 was tossed out in favor of a new computer optimized design. While perfectly acceptable for a late 70’s, low powered sedan, the rear axle design from the previous generation Mustang just wasn’t capable of providing the ride and handling characteristics of a modern performance vehicle. In other words it had reached its practical design limits. With the S197 engineers would not be constrained by being forced to use a system that had been designed for another purpose; they had a clean sheet of paper.

A pair of outboard mounted lower control arms regulated the fore/aft motions of the rear axle as it road over bumps. A third, shorter arm, called a central torque control arm, was mounted atop the differential housing. This central torque control arm was used to control axle wind-up during hard acceleration, a problem that had plagued early Fox-body Mustangs.

To control the side-to-side motions a tubular Panhard rod was installed. It was attached at one end to the axle and ran parallel to the other side of the vehicle where it was affixed to the body structure. The bushings in the Panhard rod were very firm in order to aid handling however these firm bushings did not degrade ride quality since they would not affect the motions of the three longitudinal control arms that affected the ride.

S197 Mustang rear suspension

Surprisingly the S197 Mustang rode on a solid axle rear suspension rather than the expect IRS.

The shock absorbers were mounted outside the rear structural rails and the softer springs were now located on top of the axle. Doing this allowed for the use of softer shock valving and resulted in better ride control along with better handling. For added handling prowess the GT was equipped with a 20mm rear anti-roll bar.

On the road this new suspension system was a giant leap forward for both ride and handling of the Mustang. Not only did the car ride better, it handled better too!

Along with the new suspension came all new wheel and tire packages. Base model V-6 Mustangs came with a very retro looking set of 16×7-inch 10 spoke alloys fit with P215/65R16 BF Goodrich Traction T/A tires. Upper level V-6 cars added a decorative spinner centre cap that added to the 2005 Mustang’s ‘60’s vibe.

Deluxe & Premium

Once again Ford offered the Mustang as either a Deluxe and Premium.

V-6 Deluxe: Four-wheel power disc brakes, 4.0-liter SOHC V-6 engine, five-speed manual transmission, remote keyless entry, rear window defroster, stainless steel single exhaust, dual power side mirrors, 16-inch painted cast aluminum wheels, air conditioning, AM/FM stereo with single CD player, center console, front floor mats, door map pockets, cloth front bucket seats with 50/50 split rear bench (coupe), tilt steering wheel with speed control, power windows and door locks, front air bags and LATCH system child seat mounts in rear outboard seats.

V-6 Premium adds: 16-inch bright machined aluminum wheels with chrome spinner, Shaker 500 audio system with six-disc CD changer and MP3 capability, six-way power adjustable driver seat and leather seating surfaces.

Updated Interior

Modern touches mixed with Mustang history and heritage in the 2005 Mustang interior. Chrome-ringed air vents aligned vertically across the dash, precisely in line with the gauges, and the steering wheel has three spokes with a center hub marked by the horse and tricolor bars logo, echoing the design of the 1967 Mustang.

That larger wheelbase also created more room Mustang passengers which is something that customers complained about with the previous generation car. Additional headroom and shoulder room as well as more legroom for rear passengers were obvious benefits.

As always Ford packed more standard features than ever before into the fifth generation Mustang. It got one-touch up/down power windows, power mirrors, keyless entry and power locks, a heated rear window and interval wipers. For those wanting more than the standard, Ford also had several interior packages. The Interior Upgrade Package was hugely popular. It was so popular in fact that Ford ran out of supplies and created a new package Interior Sport Appearance Package in late November, 2004.

The 2005 Mustang V6 Deluxe came standard with a single-CD player with four speakers. It has 160 watts of power. Two Delphi Audiophile systems were available in the Mustang, a Shaker 500 with 500 watts of peak power and the Shaker 1000 with 1000 watts. On cars equipped with either system, each door had its own subwoofer in a ported enclosure. This allowed the door-mounted woofers to produce more “thump” than if they were housed in the bare door. The 1000-watt version adds a mounted, ported enclosure in the trunk that includes two more subwoofers. Both systems included an in-dash six-CD changer that had the capability to play discs with MP3 computer files. This allowed customers to play as many as 200 compressed music files from one disc.

In the trunk, the subwoofer enclosure for the 1000-watt system takes up significantly less space than in the last Mustang. Computer-aided engineering enabled developers to keep its interior volume the same (to produce the same bass) while taking up less usable space in the trunk.

Special Edition Models & Variants

As always the first year of a new generation Mustang is always a little light on the special editions.

GT

The 2005 Mustang GT came in two options packages: the Deluxe and the Premium. Both packages standard items include: 4.6 liter, over-head cam, 3 valve, V8 engine; stainless steel dual exhaust; TR3650 5-speed manual transmission; fog lamps; rear spoiler; performance tires; 17 inch premium painted cast aluminum wheels, and power adjusted 6-way drivers seat with power lumbar. The GT Deluxe package comes with the standard stereo and cloth seats while the GT Premium package comes with the Shaker 500 audio system and leather seats.

Learn more about the 2005 Ford Mustang GT

San Diego Special

In 2005, Ford introduced the San Diego Special Mustang and it was one really rare special with only 200 of these were built in 2005. Known as the SDS is was reminiscent of the regional specials that were often see in the Mustang lineup in the early days of the brands history. Like those original regional specials the SDS was built for one region only and you guessed it, the San Diego Special was just for San Diego.

Learn more about the 2005 Ford Mustang San Diego Special

Yankees Limited Edition

Ford Motor company created a limited run of 60 Yankees Mustang Limited Editions in 2005. One was given to each of the Ford Tri-State Dealers in the New York area. All cars were convertibles and in a very cool touch, each Yankees Mustang came signed by a notable past or current Yankee player. They all came in white and had the Yankees stripes and logo.

Learn more about the 2005 Ford Mustang Yankees Limited Edition

Specifications, Options & Detailed Stats

Production Numbers

As was typical, the first year of the new generation saw a pop in sales, with growth up from 141,907 units in 2004 (last year of the 4th generation) to 160,412 for the new fifth generation. To dive into the model and body splits as well as see charts and percentages, check out our 2005 Ford Mustang Production & Sales Numbers deep dive.

Options and Pricing

For 2005 the Mustang got three option groups: The Exterior Sport package included a rear spoiler and lower body side mustang tape appliqué. The Interior Upgrade Package included a 6-gauge instrument cluster with 125 color lighting choices, leather wrapped steering wheel, satin aluminum finished instrument panel, air vents, door handles, scuff plates, message center and dark charcoal door panel inserts. The Red Interior Accent Package included red leather trimmed sport bucket seats, red floor panel inserts and red floor mats. This optional package requires the Interior Upgrade package and the charcoal colored interior. For more detailed options and pricing, please check out our 2005 pricing and options research.

Exterior & Interior Colors

A total of 10 colors were available for the 2005 Mustang model year. For detailed colors, color palettes, codes and interior colors please check out our in depth 2005 colors information post.

Engine Specs

The engine choices for the 2005 car include, finally, a peppy fuel injected 4.0 liter V6 producing 210 horsepower and great fuel economy. The reworked V8 was still 4.6 liters but the engine block was now cast out of lighter aluminum rather than iron; saving 75-pounds and featured a deep skirt for added strength. A host of other upgrades meant it was now producing a solid 300 horsepower. For more information on engines for 2005, you can find the information here.

Dimensions & Weight

Compared to the previous Mustang, the 2005 model was a much larger car. The wheelbase grew to 107.1-inches from 101.3, this was done to increase passenger space and improve ride quality. Most of the increase in the wheelbase was gained by cutting the font overhang and moving the front wheels forward. This not only made the car look better but also aided the vehicle dynamics by moving the front weight balance rearward resulting in a better handling car. Overall, the car was 4.4-inches longer, 0.8-inches wider and 1.4-inches taller. This increase in size directly benefitted interior space, an area that was a weakness of the previous Mustang.

Performance

Performance improved for the Mustang across the board for the 2005 model year. From a standing start the 2005 Mustang could reach 60 mph in about 6.8 seconds in base V6 guise while the Mustang GT was good for a 5.1 second sprint. The quarter mile was a decent 15.1 seconds for the V6 and the GT was a very respectable 13.7 seconds. Below we have included 0-60 mph times, 0-100 mph times as well as quarter mile times and top speed where available.

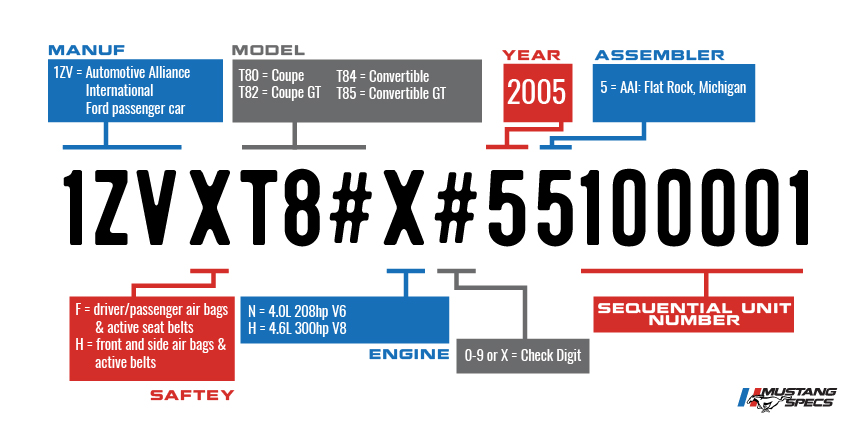

VIN Information

This link will take you to a page which contains the VIN tag information for all years of Mustangs. Previously this information appeared on each Mustang’s year page, but consolidating it has significantly reduced page loading times. To decode the build sheet, check out our 2005 VIN & Data Plate Decoder sheet.

Videos & Picture Galleries

We managed to find some great video reviews of the 2005 Mustang so definitely check those out. We also have a picture 2005 Ford Mustang Picture Gallery and photos of real Mustangs in each color that was available.